Compressor- Oil And Water Detection

Operators of large natural gas compressor systems have several ways to alert the company that a compressor lubrication system has an issue with moisture accumulation in the oil. In fact, often we are not looking at moisture contamination but water itself – in any shape or form.

What are some of the ways in which an operator knows if there is too much water in the compressor oil?

- From sample analysis

- Crackle Tests

- When a sight glass looks milky

- The compressor does not sound or feel right

Another solution is to use an inline device in tandem with oil sampling. We call this the EASZ system.

The EASZ products are inline sensors that measure moisture-water in any form while it is travelling through the lubrication system. When using dielectric methods in these situations, it is possible to measure the moisture or water content no matter what form it is in. The water could be dissolved, saturated or even free water. Yes! Free water has often been present in oil and detecting it in between samples was not possible using devices based on humidity (so called ‘water activity).

Does this mean that we do not need to sample for water in oil anymore?

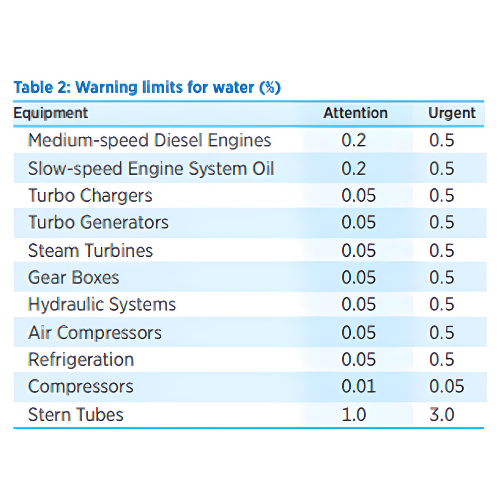

Not really! Tradition has it that oils must be sampled to keep in line with regulations and best practices. There are of course several ways to analyze an oil sample on site or in a laboratory. The question is “What happens in between oil sampling?” Unfortunately most people have no idea. With the EASZ system, an operator is alerted when an event occurs at any time of the day. Since most moisture meters cannot measure the presence of “free water” in a hydrocarbon, their implementation in a lubrication system are purely cosmetic and of no practical use. In addition, oils are normally purchased with a water content specification and are not normally expected to exceed these percentages. Here is an example of what has been recommended for certain oils.

EESIFLO TECHNOLOGIES INC.

3928 Highway 80 Rayville Louisiana, 71269

TEL: +1 (318) 614-3971

MIDLAND TEXAS

4600 FM-307 Midland, TX 79706 United States

Table Credits: https://www.chevronmarineproducts.com/

Benefits of the EASZ inline-online moisture in oil sensors

- Fastest response when water content rises

- Real-time access oil conditions

- Status of oil in between sample analysis times

- Online and inline monitoring

- Water contamination reported in understandable figure e.g ppm or percent

- Protects machinery by making operators aware of an event

- Easy to install. Costs far less than repairing broken machinery affected by too much water in oil.

- Real time measurements

- Not affected by additives or most oil contaminants

WATER IS CONSIDERED A CONTAMINENT IN LUBRICATION AND HYDRAULIC OILS

The EASZ system is in fact measuring contamination of the most commonly known contaminant – water!

The EASZ water-in-oil sensor measures water content accurately inline and online and reports the actual water content in a new or used oil.

SENSORS THAT ARE NOT LIMITED BY RANGE Water in Oil sensor for online monitoring of Water in oil.

Applications include Lubricating oil for 2 & 4 stroke engines, large compressors, oil gearboxes, turbine generators , hydraulic systems and all hydrocarbon based chemicals with low dielectric constant values.

EESIFLO also manufactures water sensors for marine oil purifiers.

Watercut Meters for the Petroleum Industry

A choice of full-bore inline watercut meters or insertion-type watercut meter probes for crude oil. Works with oil and gas separators on the liquid leg.