OIL AND WATER SEPARATION

What are oil separators?

Starting with Gravity Separators

Oil separators come in many different sizes, shapes and materials although they are commonly used to separate oil and water from each other. Oil and water do not normally mix i.e they separate naturally because of their differing densities. One of the simplest ways to separate water in oil is to give it time to naturally separate. Some engineers refer to this as Gravity Separation.

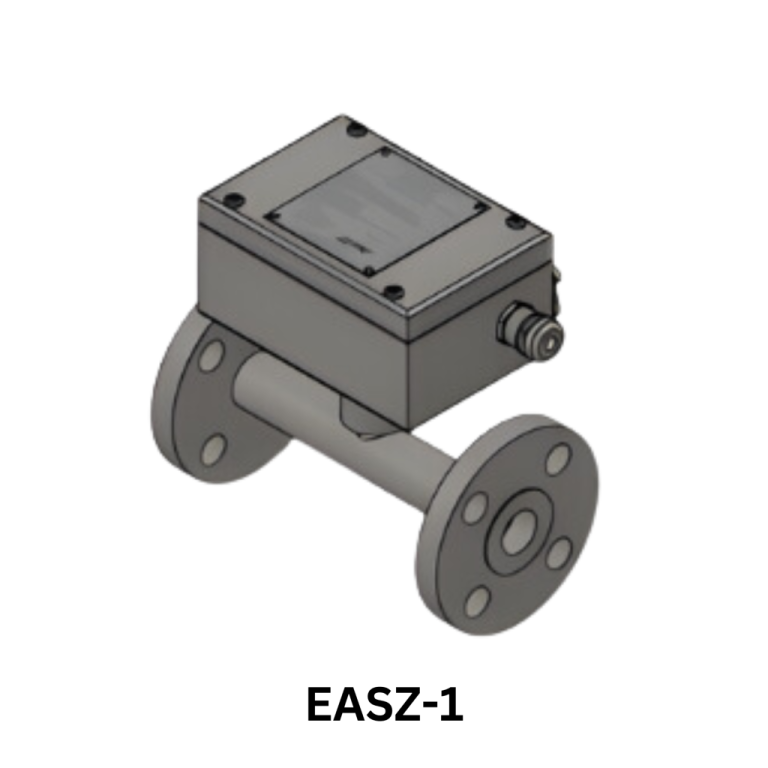

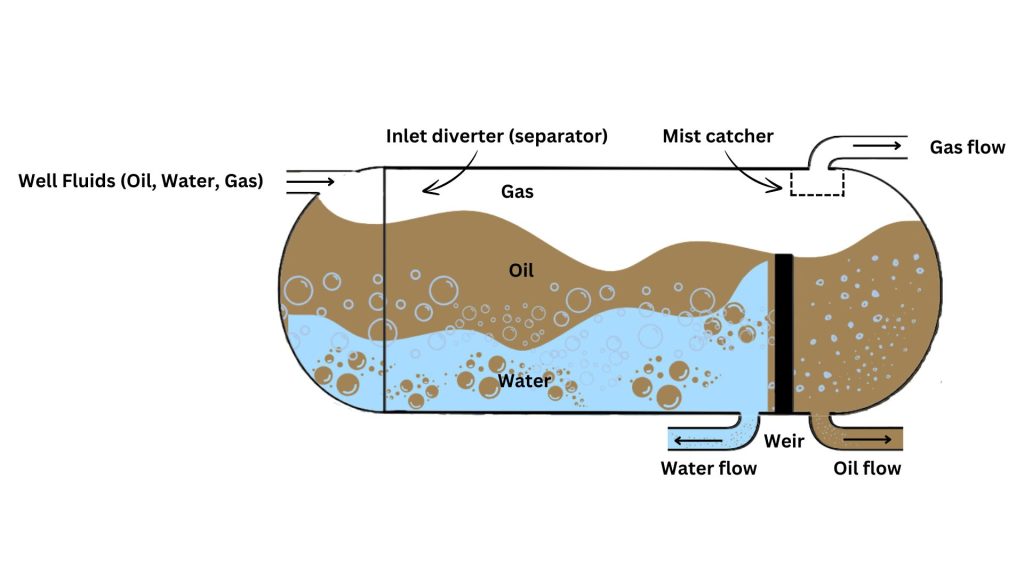

Fig 1. Industrial implantation of gravity separation.

Fig 1. Is a simplified 2D visual representation of a common type of oil separator using the gravity separation technique. The water literally sinks to the bottom of the separator where it exits a leg, while the oil floats over a weir or some engineered obstacle into a separated area where oil can exit an oil leg where a watercut meter can be installed. Fig 1. Is actually a 3 phase separator as opposed to a 2 phase separator, since the separator is completely closed and also retaining the gas portion of the fluid do that it can escape through another leg where gas will flow. This process will normally remove large amounts of oil from the water and large amounts of water from the oil, however, there will always be some contamination of water into the oil leg and oil into the water leg.

The effectiveness ( how fast a particular separator will work) depends on something called the “Retention Time” which is related to how long it will take for this technique to adequately separate fluids. The gravity separator will need to be sized and designed to take in a minimum or maximum capacity of fluid, the temperature and other factors related it. Since not every design is going to be exactly the same, it is best to contact manufacturers of gravity oil separators to find out what are the best options available

https://www.tech-fab.com/service/3-phase-separators

3 Phase Separators

Ideal for Oil, Gas and Water Separation: Tech Fab fabricates advanced, precision 3 phase separators primarily used in the oil and gas industry to separate outflowing raw petroleum from a body of water. Our three phase oil and gas separators work by dividing water, oil, and gas from well effluent, facilitating continuous production with no need to interrupt ongoing work to perform repairs or maintenance tasks on wells.

Expert 3-Phase Oil & Gas Horizontal Separator Fabrication

To learn more about our 3-phase horizontal separator fabrication, or for detailed information about oil & gas separator machine specifications and costs, contact a member of the Tech Fab team by calling (281) 862-9001.

Fig 2.0 visualizing centrifugal force

Centrifugal separators will exploit centrifugal forces which are produced by spinning. It is possible to feel the effects of centrifugal forces in an amusement park where customers sit on the insides of a spinning wheel. While the wheel rotates, a centrifugal force is produce which makes the body feel as if it is being flung outwards. In centrifugal separators ( often called centrifuges, high speed oil purifiers, lube oil separators, fuel oil separators) the centrifugal force makes the denser water particles tend to move outwards against the inner wall of the separator while the lighter particles move inwards so that there is separation. This technique is very popular when more rapid separation is needed, especially in the case of large oil emulsions.

Watch how this works. Compliments of Haus Centrifuge

Oil Separators Purifiers Centrifuges

Through a system of gears, a centrifuge bucket type object (often referred to as a bowl) rotates at high speed. When the machine is on and the rotational speed is sufficient, the oil to be separated enters the cavity. Denser components in the oil begin to move away (outwards) while the solid particles that are too fine to be removed by filtration are forced towards the circumference of the bowl. Water tends to drop towards the bottom.

What are other types of oil /water separation techniques?

There are other ways to separate water such as the use of filters and coalescing techniques.

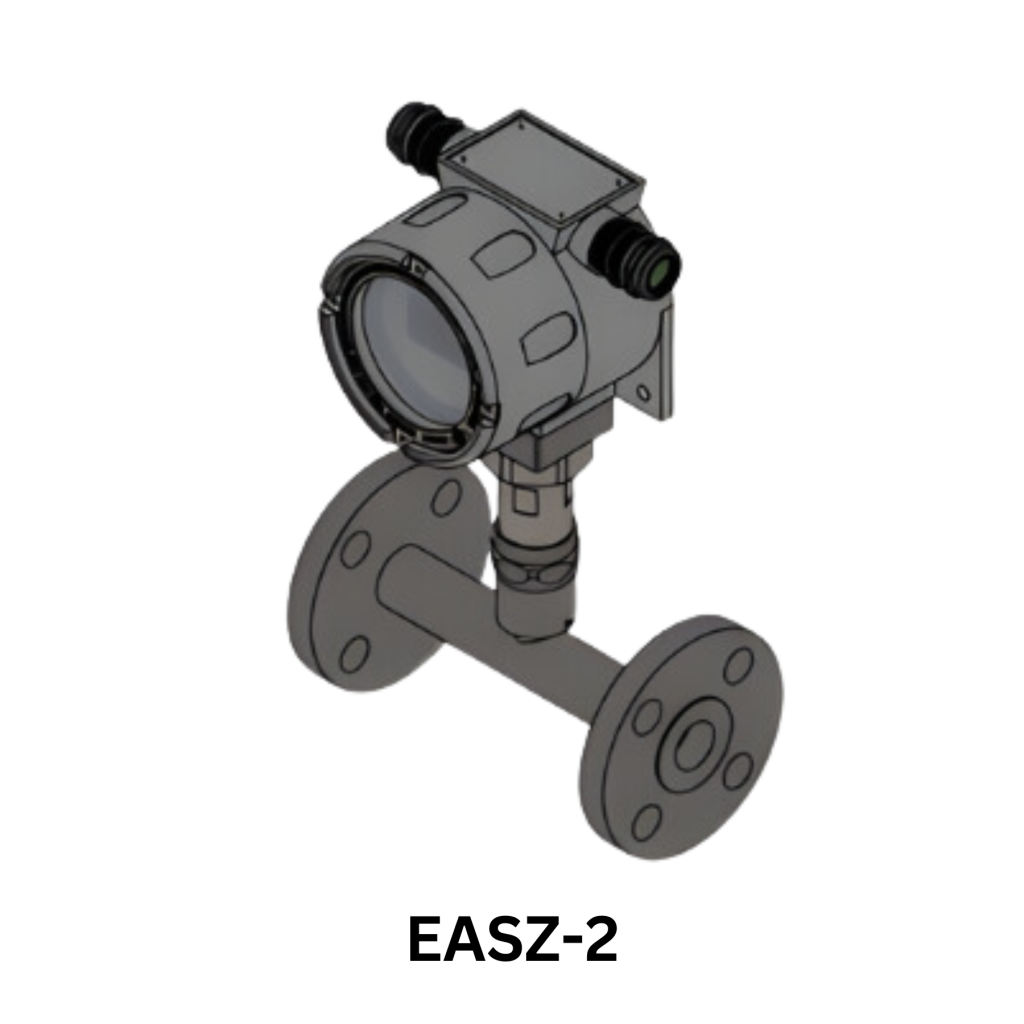

Continuous Monitoring of Water in Oil Concentration in Lubrication Systems for Purifiers and Centrifuges

Water contamination is something that needs to be monitored in purifier lubricating oil. We have developed a sensor that works on any type of oil whether it is mineral or synthetic.